Introduction

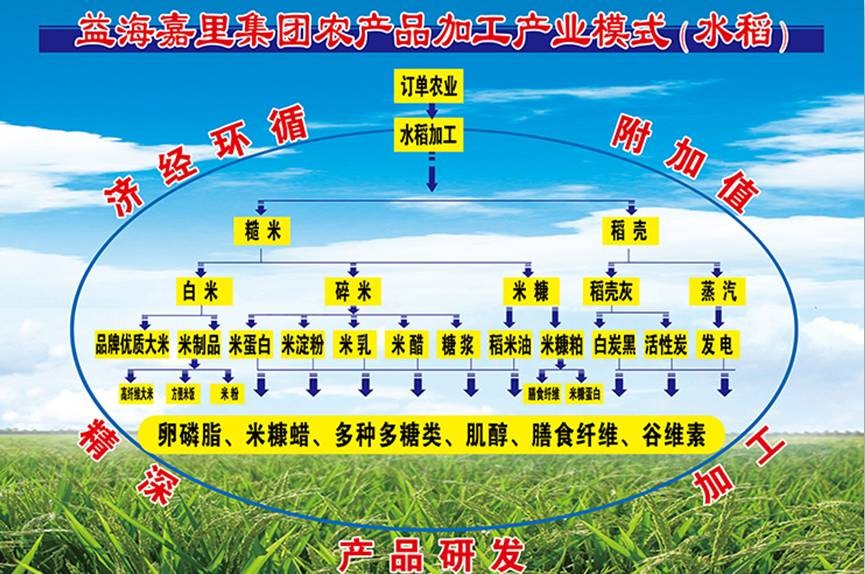

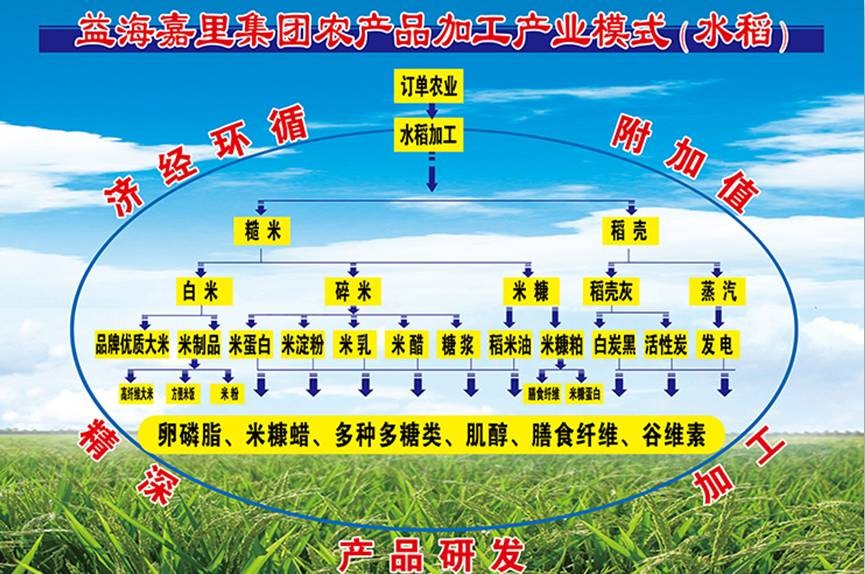

Rice circular economy

On August 26th, the "APEC Workshop on Food Loss Reduction Technology and Experiences for Smallholders and Small and Medium-sized Enterprises" was held in Beijing within the framework of the Asia-Pacific Economic Cooperation (APEC) Food Security Policy Partnership Mechanism (PPFS). Wang Wei, Director of Public Affairs Department of Yihai Kerry Group, briefed the representatives of the participating economies on the exploration and practice of "Yihai Kerry Rice Recycling Economy" and how to realize the grain loss reduction and promote the national agricultural industry through this model.

On August 26th, the "APEC Workshop on Food Loss Reduction Technology and Experiences for Smallholders and Small and Medium-sized Enterprises" was held in Beijing within the framework of the Asia-Pacific Economic Cooperation (APEC) Food Security Policy Partnership Mechanism (PPFS). Wang Wei, Director of Public Affairs Department of Yihai Kerry Group, briefed the representatives of the participating economies on the exploration and practice of "Yihai Kerry Rice Recycling Economy" and how to realize the grain loss reduction and promote the national agricultural industry through this model.

For a long time, China's rice cultivation and processing are mostly in the scattered planting, extensive processing, inefficient situation, "small, scattered, low" processing pattern exacerbated the loss of food losses, rice processing industry needs to be upgraded. "Waste not only at the table, waste still exists in the grain storage, processing, circulation and other links." Wang Wei speech began to emphasize Road.

According to reports, Yihai Kerry since Heilongjiang in Jiamusi in 2006 to establish the first rice processing and production base, adhere to the rice processing industry in-depth analysis, and in 2008 the first leading global rice circular economy model, scientific help Grain loss, vigorously promote the upgrading of agricultural industries.

Among them, the order of agriculture, is Yihai Kerry rice recycling economy, the primary part. Yihai Kerry through the high-quality varieties, excellent origin, the price of the acquisition, optimization of the four preferential orders for agriculture, planting, purchasing and storage, processing, consumption combined to effectively solve the problem of low efficiency of the agricultural industry. Up to now, Yihai Kerry has been in the country's eight major rice cultivation provinces, the establishment of 29 high-quality rice ecological base.

According to the data provided by Yikai Kerry, the order farming model can increase 220 RMB dollars per ton of rice, according to its annual processing capacity of 3 million tons of rice, a total increase of about 600 million RMB dollars. If the push and the whole industry, according to China's annual rice output of 200 million tons, can increase about 45.5 billion RMB dollars.

Wang Wei also said that for Yihai Kerry, food is not simply save food, damage is not simply reduce the loss, grain loss is a broad concept, the efficient use of arable land resources, increase the unit of land output value, An important way of diminishing grain.

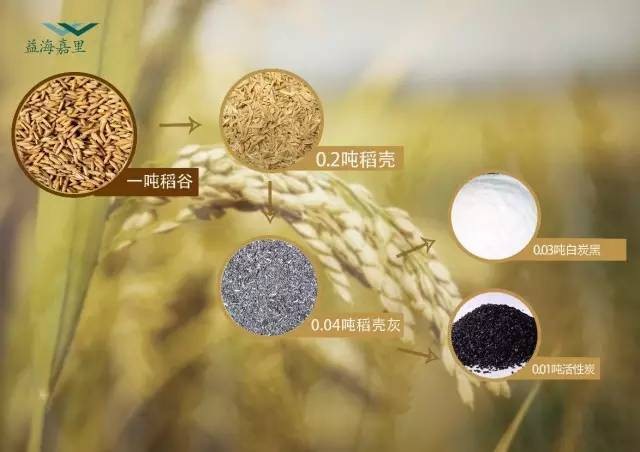

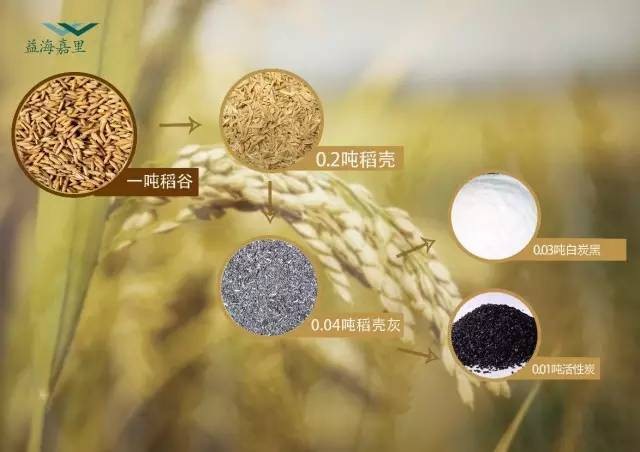

It is reported that, in accordance with Yihai Kerry "rice circular economy model", on the basis of large-scale processing, in addition to the production of high-quality brand of rice, such as the familiar dragon fish series of rice, after the rice plant after processing by-product rice bran can be refined and produced Processing of rice oil; from rice bran oil by-product of refined fatty acids, rice bran wax, rice bran fat, oryzanol, ferulic acid, is widely used in special oils, oil chemicals, cosmetics and other industries, efficient use of resources. The most technical difficulty and scientific and technological content is the rice husk power generation, rice hull ash made of activated carbon and white carbon black.

"In the process of research and development, we overcome a lot of difficulties, but in the end we do the rice husk as a fuel in the dedicated power generation boiler combustion, resulting in the production of rice hull, The high-temperature and high-pressure steam is used for power generation, and its power generation per ton of rice hull is equivalent to 0.65 tons of coal from electricity. From the cost accounting, it can be concluded that the processing of one ton of rice husk ash can yield about 800 RMB dollars per year, With 36,000 tons of rice husk ash calculation, profit of 22.8 million RMB dollars.

In addition, Yihai Kerry use of rice husk ash to obtain activated carbon, white and other high value-added products, the technology has also been applied to the actual production.

It is understood that extracted from the rice husk ash is pure natural renewable resources, can be widely used in chemical and tire rubber and other industries. Yihai Kerry to renewable resources rice husk ash as raw material, a ton of rice paddy rice can produce 0.03 tons of high value-added silica. This high dispersion of carbon black overcomes the problem of poor performance of traditional silica, which significantly increases the strength of the rubber and helps reduce tire rolling resistance, improve fuel efficiency, and green.

July 2016, one of the world's three major tire giants Goodyear Tire Rubber Company and Yihai Kerry cooperation, the use of rice husk burning ashes made of green carbon green production of green fuel-efficient tires, through industry cross-border joint, to promote green sustainable development.

"At present, Yijia Kerry's rice processing capacity accounts for only 1% of the total rice production in the country, the production of high-dispersion-agent-class white carbon can not meet the demand for green tire manufacturing, the global annual production of more than one billion tires, We can see that the development of this industry is huge, we eagerly hope that the benefits of sea Kerry in the use of rice husk ash to obtain white carbon technology can be widely used in the country and the world to promote the application. "Wang Wei finally said to Xinhua food.

Yihai Kerry rice circular economy for each grain of rice "eat dry pressing" model of the transformation and upgrading of the world rice industry has a leading role model. We look to the future, if you can promote in China and the world, will have far-reaching significance for global agricultural change.

Process Map

Rice circular economy model cross - border automobile industry

One of the world's three largest tire giants, Goodyear Tire Rubber, announced that "cooperation with Yikai Kerry, the use of rice plus the production of chaff waste to produce green fuel-efficient tires."

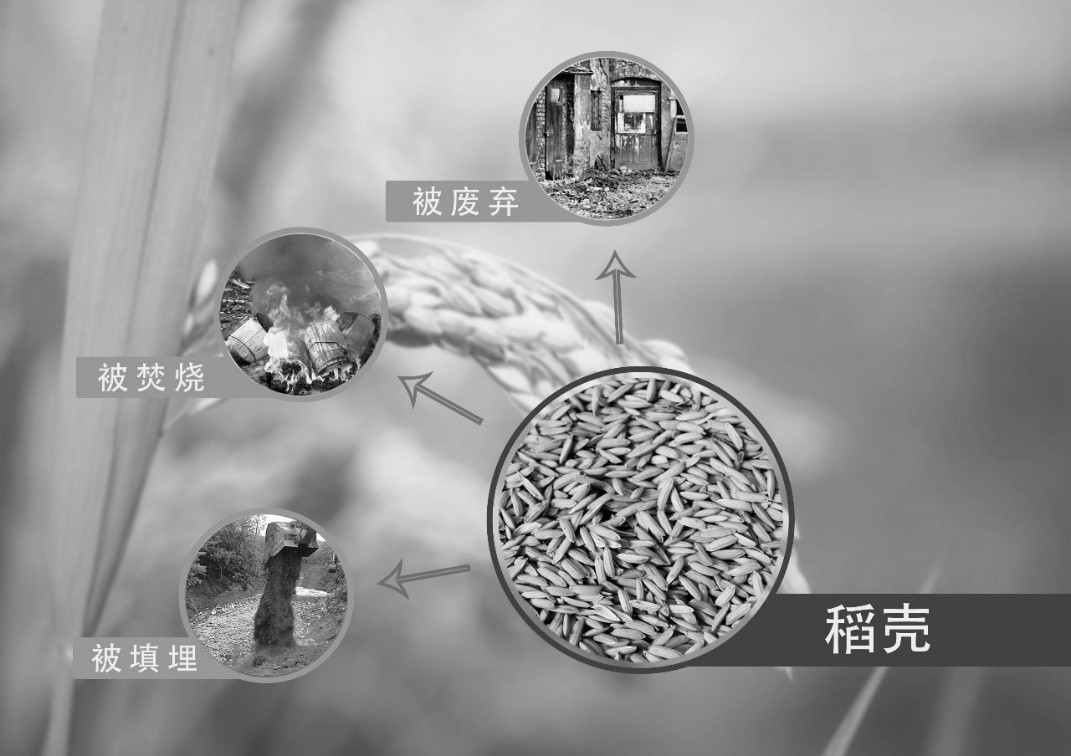

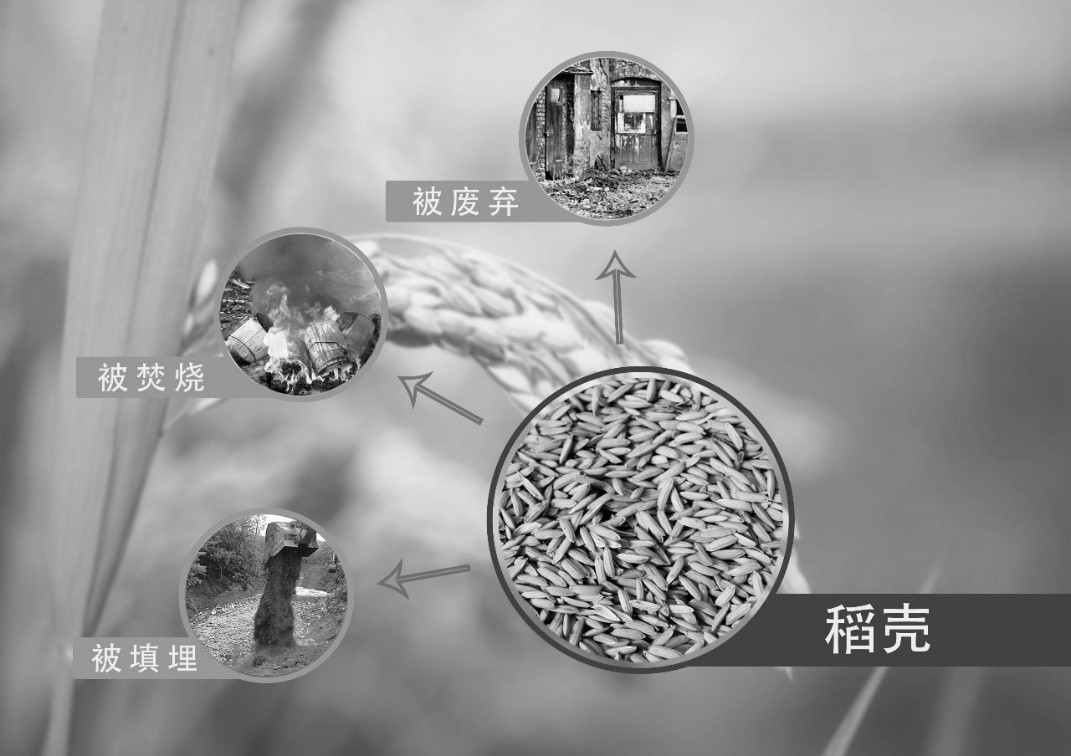

Rice is one of the world's largest food varieties, but in rice growing areas, rice husk treatment is a daunting environmental problem, a large number of rice hulls are abandoned each year. Some companies generate electricity through rice husks, which generate heat by using rice husk combustion, which produces tens of thousands of tons of dust, and the rice husks produced by the rice husk burns are only treated as ineffective.

Rice husk incarnation of white carbon black

Yihai Kerry uphold the "eat dry pressing net" circular economy environmental protection principle to rice husk ash this renewable resources as raw materials, the rice incineration into silica, after extraction, precipitation and other processes can produce a ton of rice 0.03 Ton of high value-added white carbon black (scientific name "amorphous hydrated silicon dioxide") was born.

Why is white carbon black used for tires

Silica is an important component of the tread rubber formulation, which increases the strength of the rubber and helps reduce tire rolling resistance, while the lower tire rolling resistance can improve the fuel economy of the vehicle. Most of the silica in today's market is extracted from the ore, and the refining process itself needs to consume a lot of energy.

Goodyear found that the silica converted by rice husk incineration could match other types of silica in terms of rolling resistance and provide better wet slippage of the road, and this new type of silica has many benefits to the environment Reduced waste landfill saves energy during processing. Based on the above considerations, Goodyear carefully selected Yihai Kerry as this new type of silica suppliers.

Yikai Kerry first rice husk filling agent level

White carbon plays two roles in the tire: filling and reinforcing. Traditional white carbon black is the main role of filling, and poor performance, direct lead to tire wear and fuel efficiency is low, so despite the realization of rice husk ash into silica for many years, but only in the latest technology transformation process Preparation of new silicon dioxide (ie, highly dispersed silica), only to achieve a high standard for the use of green tires. And the benefits of Kerry has the ability to convert rice husk ash into high-dispersion white carbon (also known as the reinforcement class of white carbon black), and was used to replace ordinary white carbon for tire production. Compared to the low dispersion coefficient of conventional silica, it can significantly increase the strength of rubber and help reduce tire rolling resistance.

The challenge still exists

However, the supply of reinforcing agent-grade silica is still a problem. At present, the high-dispersion-supporting grade silica produced by Yikai Kerry can only meet the tires that are more environmentally friendly because of Goodyear A small part of the manufacturer's needs, not to mention the needs of the industry - the global production of more than one billion tires per year. Recycling of circular economy, the impact on the environment will be huge and far-reaching.

Reinforcement Grade White Carbon - One of the Cyclical Economy of Rice in

Paddy incineration is converted into a reinforcing agent grade silica, which is only one part of Yihai Kerry rice recycling economy. Yihai Kerry from 2006 in Heilongjiang Jiamusi to establish the first rice processing and production base, adhere to the rice processing industry in-depth analysis. After years of painstaking research and development, Yihai Kerry first global high-quality rice recycling economy model: "through the selection of varieties, order agriculture, so that enterprises and farmers, agricultural cooperatives to become the interests of the community, so that one or two industrial organic integration, , Business benefits. "

According to this model: If the country about 190 million tons of rice processing rice bran are used for oil can produce about 2.2 million tons of rice oil, the equivalent of 110 million mu of land for the country to save arable land. If the country's rice husk can be used to generate electricity can replace 22 million tons of standard coal, can produce 20 billion kWh corresponding to reduce the emissions of 300,000 tons of sulfur dioxide.

Regardless of how the future market direction changes, the development path of the eco-economy of Yijia Kerry has been clear and clear, that is, to establish a complete industrial chain and to increase the comprehensive utilization of resources through deep-level model research and technological innovation Output value, protect the environment, "promote the coordinated development of resource development and environmental protection to improve the overall environment of the Earth." This is the commitment of Yikai Kerry to building an environment-friendly society as well as support for the future initiative to respond to the concept of sustainable development.

Regardless of how the future market direction changes, the development path of the eco-economy of Yijia Kerry has been clear and clear, that is, to establish a complete industrial chain and to increase the comprehensive utilization of resources through deep-level model research and technological innovation Output value, protect the environment, "promote the coordinated development of resource development and environmental protection to improve the overall environment of the Earth." This is the commitment of Yikai Kerry to building an environment-friendly society as well as support for the future initiative to respond to the concept of sustainable development.