Beef Products Inc.

Problem:

In beef production, a typical live steer weighs about 1,300 pounds generates roughly 850 pounds of usable meat and bone after the carcass is dressed. We normally consume beef as beef steak. However, only about 20 percent of the dressed carcass is comprised of steaks. The other 80 percent cuts like roasts, ribs, and flanks. Consequently, almost half the carcass finally winds up as ground beef.

Ground beef is often made by beef trimmings which are left after the trimming process. However, some beef trimmings are too fatty to be of much use in the process, particularly as consumers have come to demand leaner ground beef in recent decades. The result was that lots of perfectly edible beef was rendered useless and not eaten by humans.

Solution: To make leaner ground beef from these fresh trimmings, Beef Products Inc. (BPI) developed a precision method using a specially designed centrifuge. It is similar to the process used to separate milk from cream and make low-fat milk.

1. How Lean Finely Textured Beef is made in BPI plant?

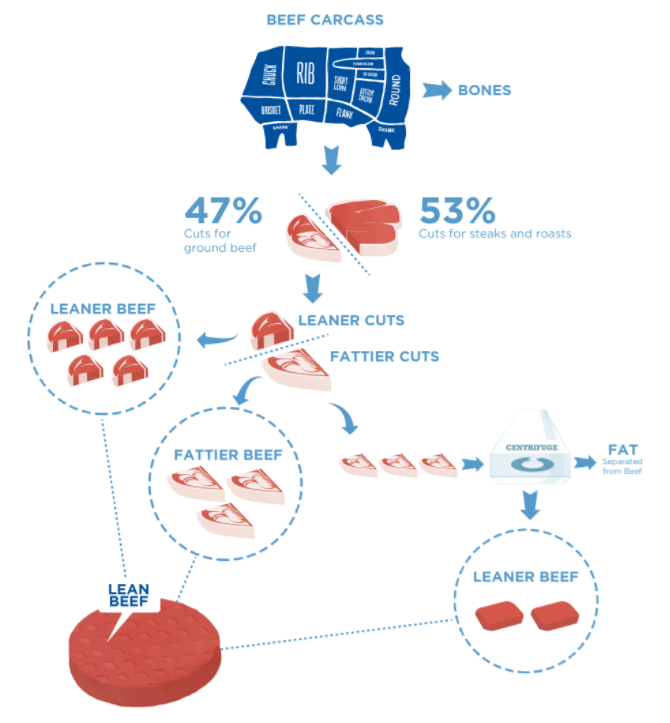

- BPI plants are usually set up next to Tyson which is a food company. From the cutting floor of Tyson plant, beef is divided into cuts, 53% goes to steaks and roasts and 47% are cut for ground beef known as beef trimmings (Figure 1).

- Fatty beef trimmings from the cutting floor of Tyson then go directly on a conveyor connects to BPI plant where fat is warmed and separated from lean by a centrifuge. BPI uses the centrifuge spins at high speeds to separate heavier elements, like lean meat from light elements like fat. The centrifuge simply removes the fat that cannot economically be done by a knife. The remained lean is literally the same beef that was in any other roasts or beef trimmings.

- While the beef is in the process, it is exposed to puff of ammonia in the form of ammonium hydroxide. Ammonia can elevate the pH quickly so any type of pathogen cannot survive. BPI does this to guarantee the beef is being safe and nutritious.

- The lean is then passed over the chilled metal rollers where it quickly freezes, the product becomes known as “lean finely textured beef.”

- BPI ships the lean finely textured beef to other processors, food manufacturers, and restaurants where it is typically mixed with other cuts and beef trimmings (often at ratio of one pound of lean finely textured ground beef to seven to nine pounds of beef trimmings) to make hamburgers and lean ground beef.

- The entire process takes only about 15 minutes. No human hand ever need to touch the food from the time it enters till it leaves the plant.

Figure 1. The process of making lean finely textured beef in BPI

Figure 1. The process of making lean finely textured beef in BPI

2. Food Safety Innovation

-

The process of making lean finely textured beef has been recognized repeatedly for its innovative contributions to food safety. This process includes many steps. Two of the most critical is ammonium hydroxide and hold and test program.

-

Ammonium Hydroxide: Ammonia is an essential nutrient present in meat and in most foods. In BPI beef, the natural amount of pure ammonia, in the form of ammonium hydroxide, is added because it is a powerful defense against potential germs. Thus, the beef is provided as the safest as possible to consumers.

Refer to Ammonia in Foods: https://www.youtube.com/watch?time_continue=29&v=7Fj81Ljx58s

-

Hold & Test Program: The beef is continuously sampled and tested with the most rigorous standards in the industry, ensuring the safety and quality beef provided to consumers.

3. Lean finely textured beef helps to decrease market prices of beef and reduce food waste

-

BPI’s product is 95 percent fat-free; thus, it is used to help meet the demand for 90 percent and 95 percent lean ground beef, reducing the price of 90 percent lean ground beef by 4 percent.

-

BPI has estimated that if we stopped eating lean finely textured beef, it would be equivalent to “throwing away 5,700 cattle a day.”

-

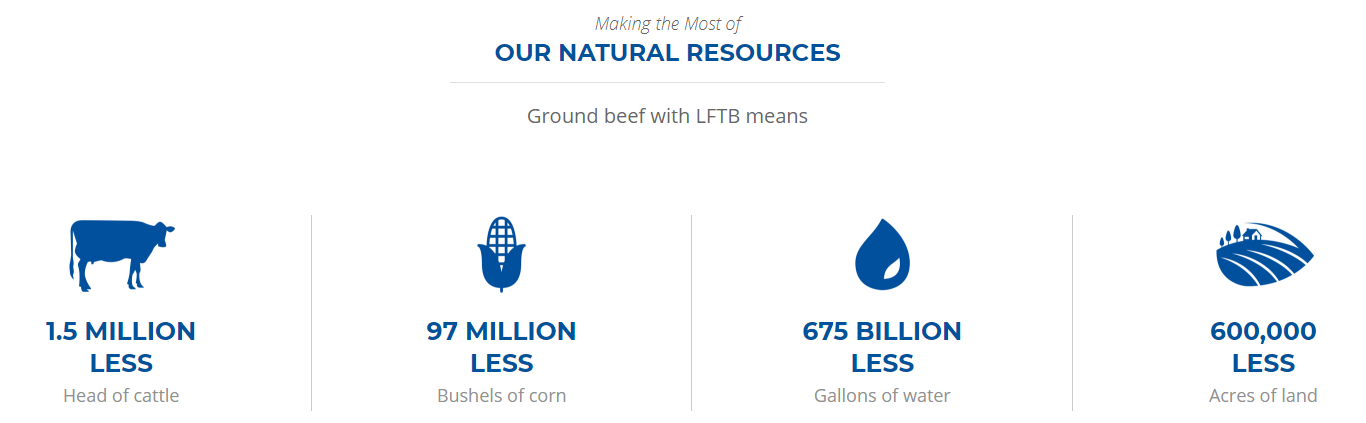

BPI commits to environmental responsibility and sustainable agriculture. By producing the beef in an innovative way, BPI estimates that 20,000 fewer cattle need to be processed every week to supply the lean beef demands of consumers.

-

It takes 16,000 litres of water to produce 1kg of beef – said Arijen Hoekstra, the University of Twente. BPI contributes to the sustainable food system directly by reducing food waste of meat sector and indirectly by saving the resources to produce food.

Jayson Lusk, Unnaturally Delicious: How science and Technology are serving up Super Foods to Save the World. New York: St. Martin’s Press, 2016. https://www.beefproducts.com/