Persimmon Astringency Vacuum Processing

Product Type: Fruits - persimmon

Stage: Production & Harvesting, Handling & Storage

Problem: Occurrence of astringency in persimmon fruits during storage and prior to processing or sale

Solution: Postharvest vacuum treatment designed to reduce astringency of persimmon fruit: persimmon fruit are placed into vacuum bags and pressed by vacuum. The process reduces astringency while avoiding the negative visual outcomes of the conventional lime-soaking treatment for persimmon astringency.

- Persimmon fruit typically needs to be treated to reduce astringency before use or consumption. The conventional method for reducing astringency is to soak the fruit in lime. Lime-soaking results in a layer of white powder covering the persimmon fruit which makes it unsuitable for sale or consumption. A vacuum-based method for de-astringenting solves the problems posed by the lime-soaking method.

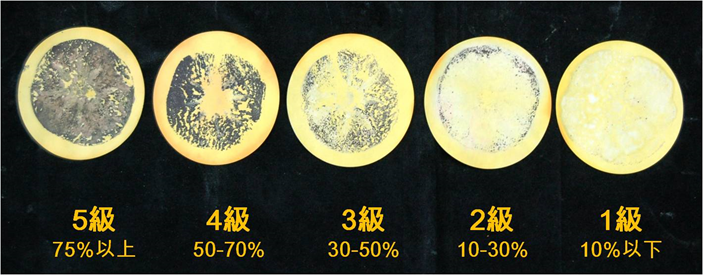

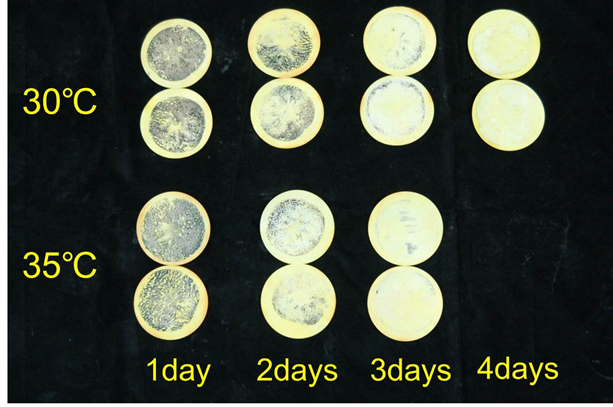

Black areas on the face of the fruit are tannins contained within the persimmon. Chemical reactions of the tannins color the persimmon black which makes it unsuitable for processing, consumption, or sale. Tannin-affected surface area of the fruit is divided into five grades on the index. Grade 1 means 10% or less of the fruit is affected by tannin coloration, Grade 2 represents 10-30%, Grade 3 represents 30-50%, Grade 4 represents 50-70%, Grade 5 represents 70% and above. Fruits of Grade 1 or 2 are of commercial value. - Persimmon fruit in the top row have been treated with the conventional lime-soaking process for deastringenting. Fruit in the bottom row have been vacuum-processed.

- Persimmons placed in vacuum bag for vacuum treatment

- After vacuum treatment, persimmon fruit astringency is suitably reduced and appropriate for use after three days if allowed to settle at 30℃ and after two days if allowed to settle at 35℃.

Resource :

Ching-Chang Shiesh